Here are some examples of how the introduction of work inspection cameras has prevented human error and improved work efficiency.

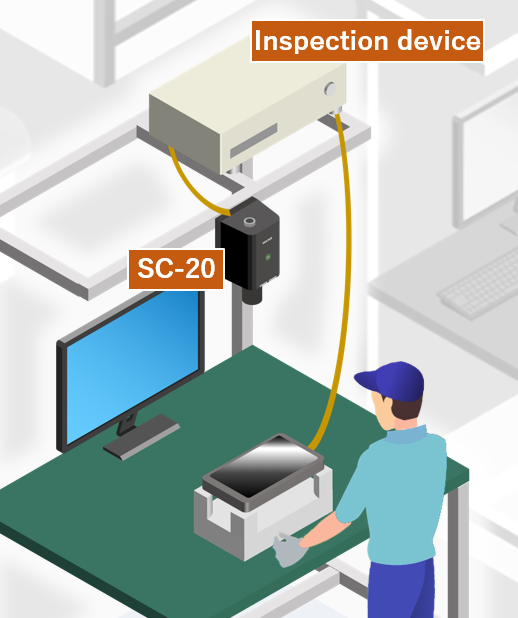

Work inspection cameras are used in a variety of ways on the manufacturing lines at Ricoh's Tottori factory.

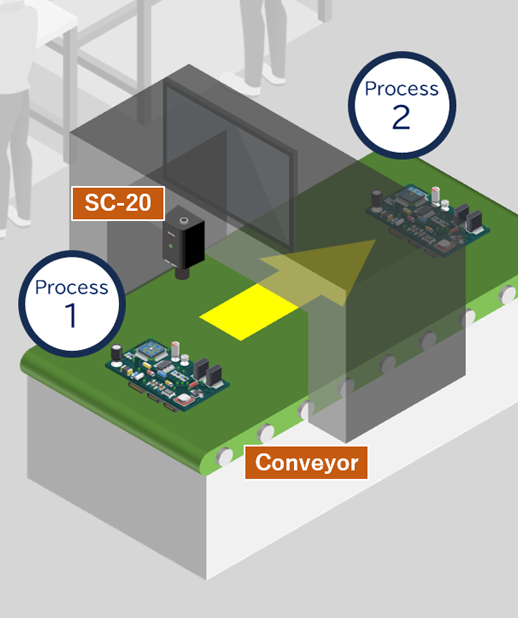

This is an example which demonstrates that the contents displayed on the panel can be inspected in addition to the inspection of the assembly operations.

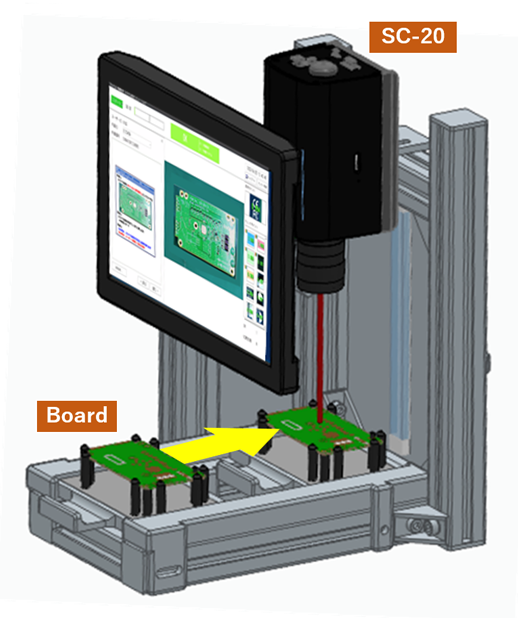

Example where the inspection accuracy, inspection efficiency and worker’s workload were all improved through utilizing dedicated jigs and limit switches.

This is an example of the use of SC-20 in combination with the factory equipment, which not only automated manual inspections but also reduced unnecessary walking movements by workers.

This example shows SC-20 being applied to inspect a three-dimensional object, which is usually difficult to inspect solely with SC-20, by combining a variety of additional devices.

Improved efficiency and quality at the same time.

Prevents assembly mistakes and process skipping.

Prevents omission of parts that had not been detected by visual check.

Achieved quality assurance and traceability at the same time.

These are examples of customers who have actually implemented and used the system.

How RICOH SC-10A, Automated Vision Inspection System solved customer's problems

Usage and introduction examples for the RICOH SC-10A

(Customers' opinions in manufacturing industry)