SC-20 is basically a product that inspects assembly objects by directly capturing images with a camera mounted inside the main unit.

However, since there are no limits to the objects that can be captured by the camera, as long as the image difference is recognizable, it is also possible to inspect the display of visualized images.

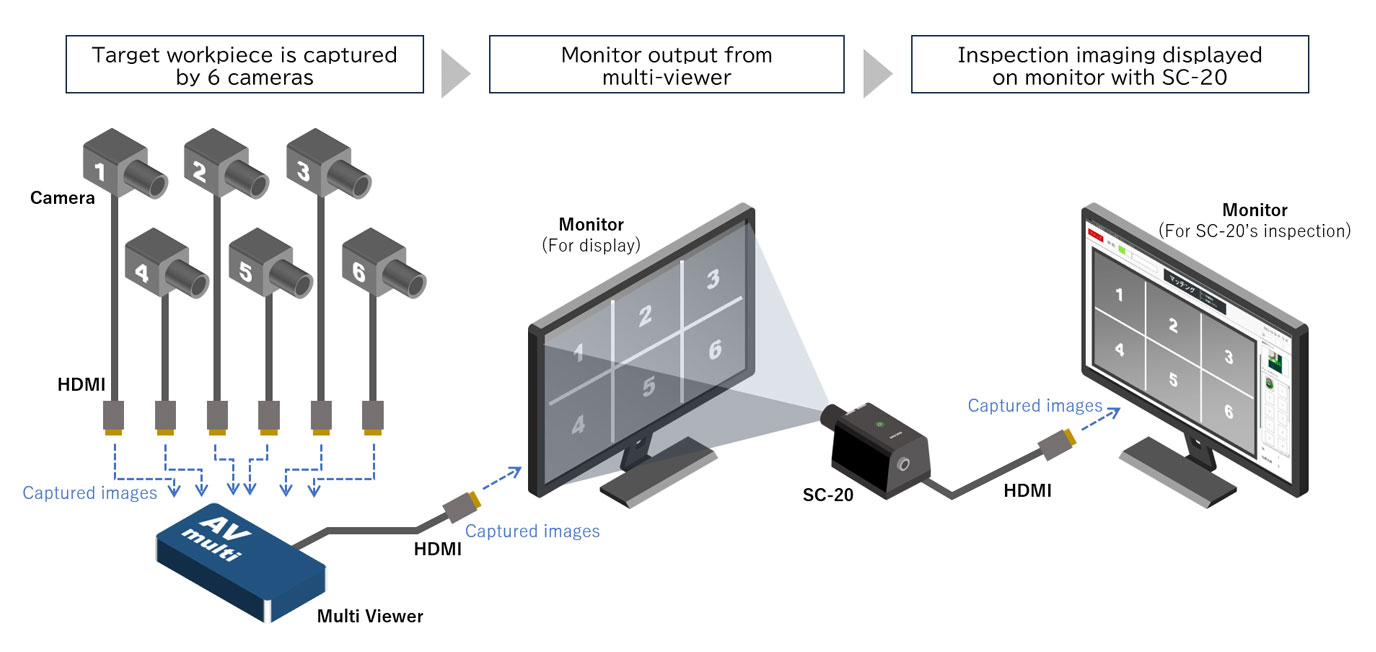

Utilizing this property, a system was constructed to inspect images captured from multiple cameras at various angles, being displayed on multiple LCD monitor, using the SC-20's “shape” matching mode.

- Six cameras were installed to capture images of multiple parts of the product to be inspected, from various angles.

- The HDMI signals from each camera were collected and displayed on a separately prepared LCD monitor via a device that generates multiple images (HDMI multi-viewer).

- SC-20 was set up to capture images of the LCD monitor display, by installing the image of the product in its completed state as a master image. The rest of the setup was the same as a normal inspection setting.