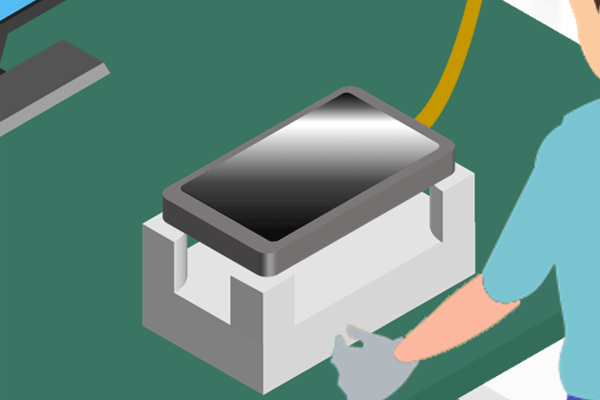

Conventionally, inspection programs were run on a single inspection machine, and functional tests were conducted by worker’s manual inspection.

The inspectors were required to manually inspect the characters displayed on the device's screen to assure that the functions were running correctly.

The inspectors were required to manually inspect the characters displayed on the device's screen to assure that the functions were running correctly.

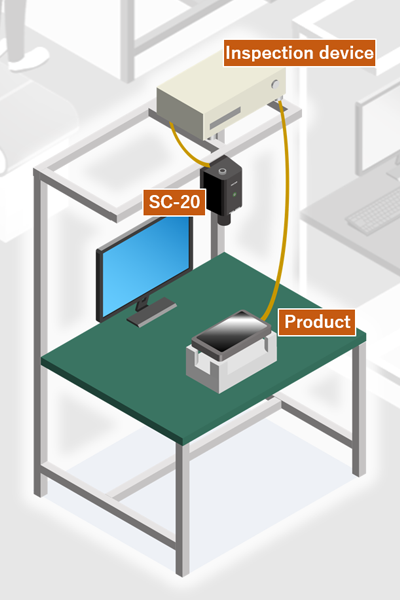

- The display image of a correctly functioning product was registered as a master image on the SC-20 in advance, and work IDs were created for each of the multiple programs.

- Whenever a product is set in the fixed jig and SC-20’s inspection is started, the inspection device activates the inspection program, displaying the default character string on the product screen.

- The displayed condition is inspected in the [shape] matching mode of SC-20, and if it is judged as an OK product, the device activates the next inspection program.

- The process above is repeated, and the whole inspection process for this product is completed automatically.