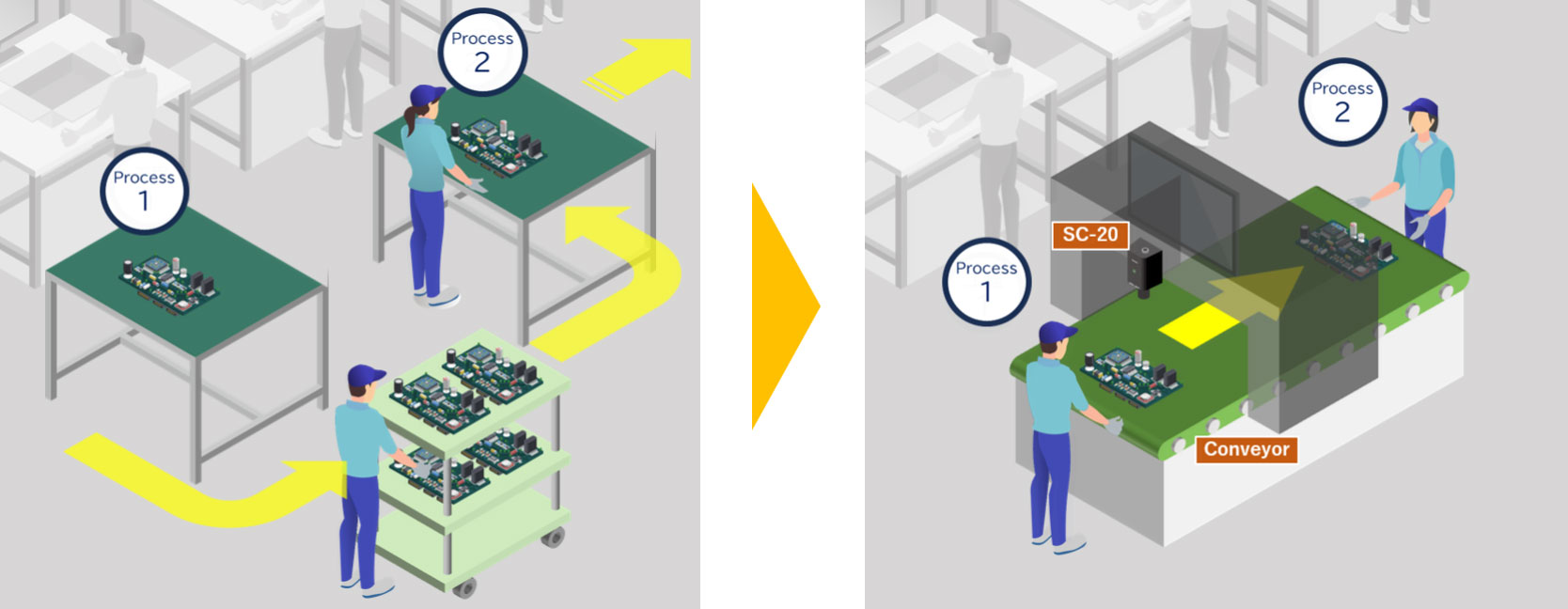

An example of successfully reducing both takt time and man-hours by linking the product transfer process with SC-20’s inspection.

The conveyor is triggered by SC-20's inspection results, and the products are automatically transferred to the workbench in the next process, eliminating the manhour to carry around the product with a cart.

This is an example of the use of SC-20 in combination with the factory equipment, which not only automated manual inspections but also reduced unnecessary walking movements by workers.