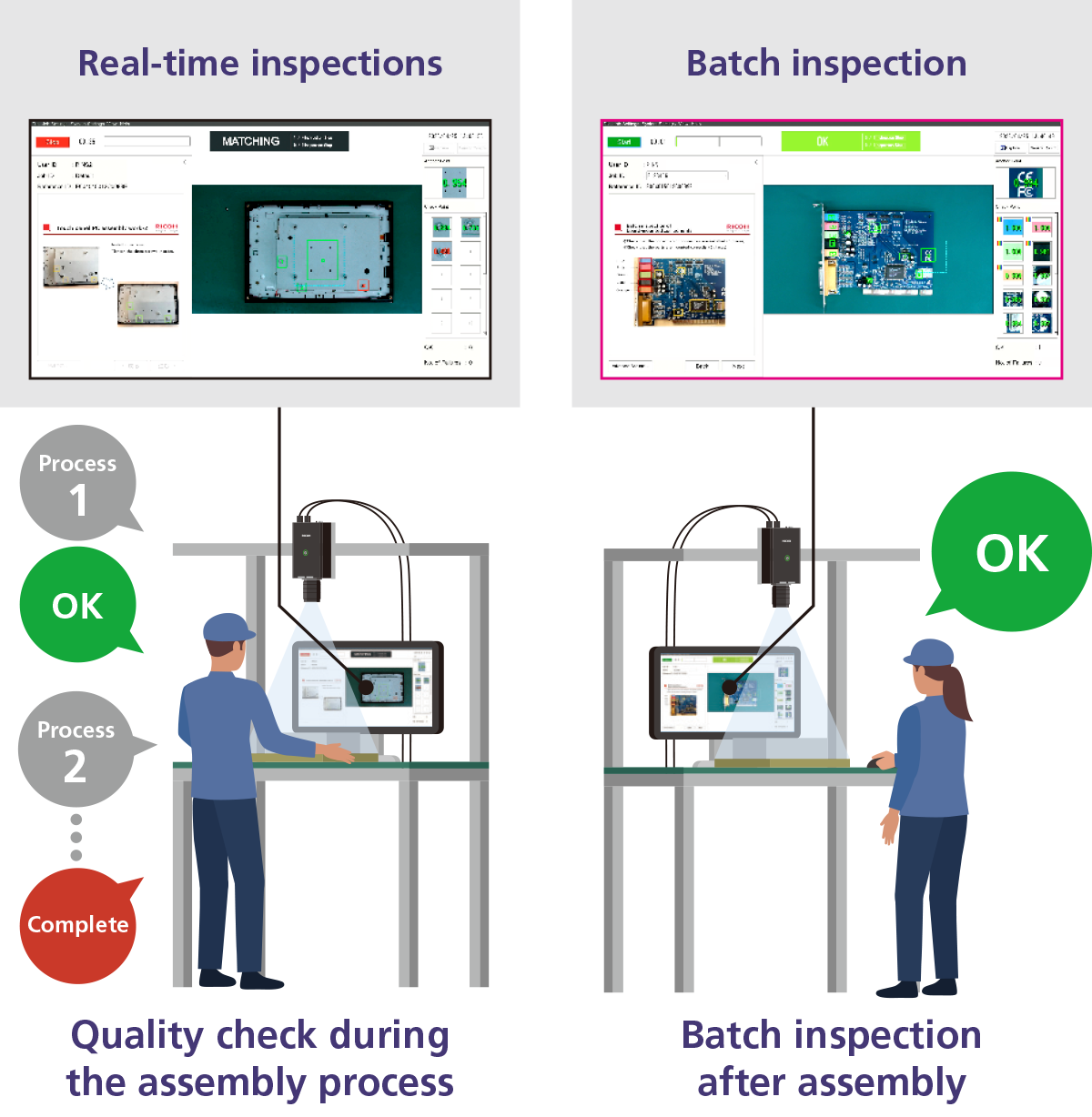

The RICOH SC-20 is a work inspection camera that detects mistakes during the assembly process. It can conduct real-time quality checks during a job, something exterior inspection cameras are not capable of. It can perform automatic checks of assembly status such as similar parts, missing parts, and work order, and perform batch inspections after a job is completed. Because the system is easy to set up without the need for a computer, it is easy to begin digital inspections.

Image recognition automatically checks assembly status during the job. Digitalization of visual inspections helps maintain consistency. You can set up to 20 check points and perform batch inspections after a job is completed.

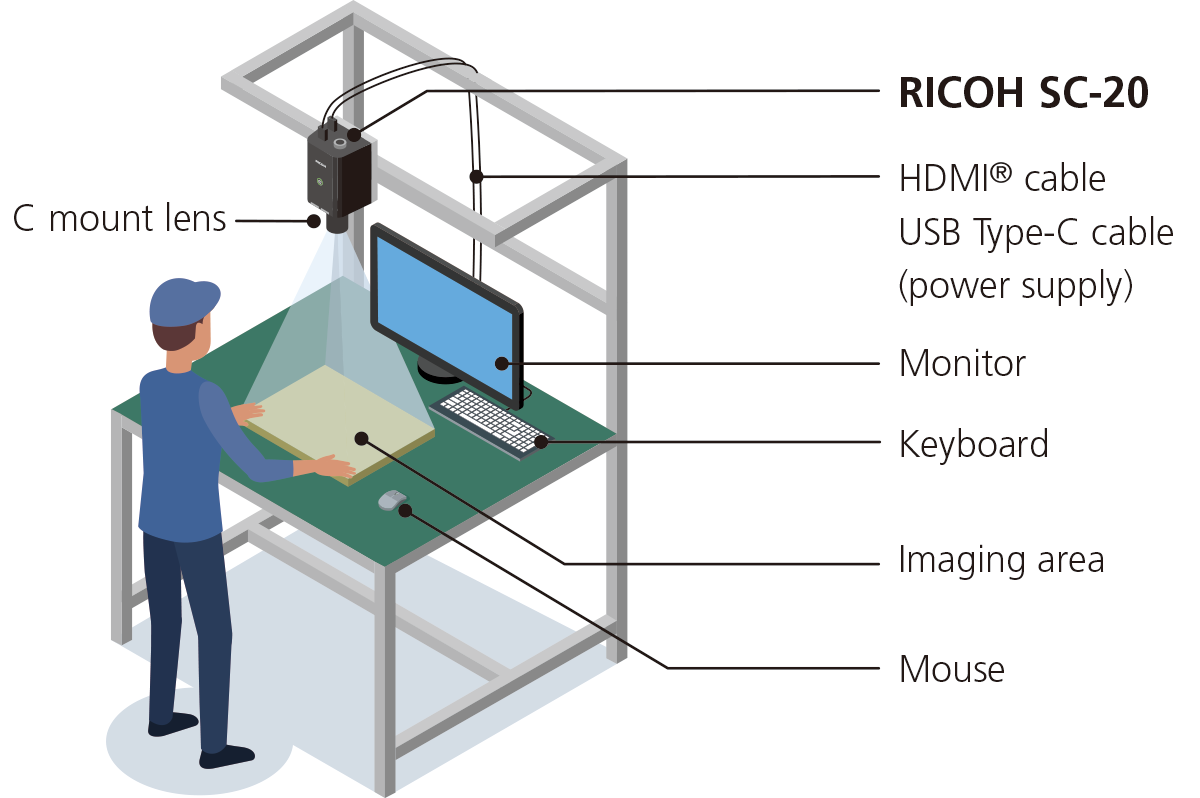

The camera, image recognition, and software are integrated. The system is easy to set up if you have a mouse, keyboard, and monitor. If you have a touch panel monitor, you don't need a mouse or keyboard.

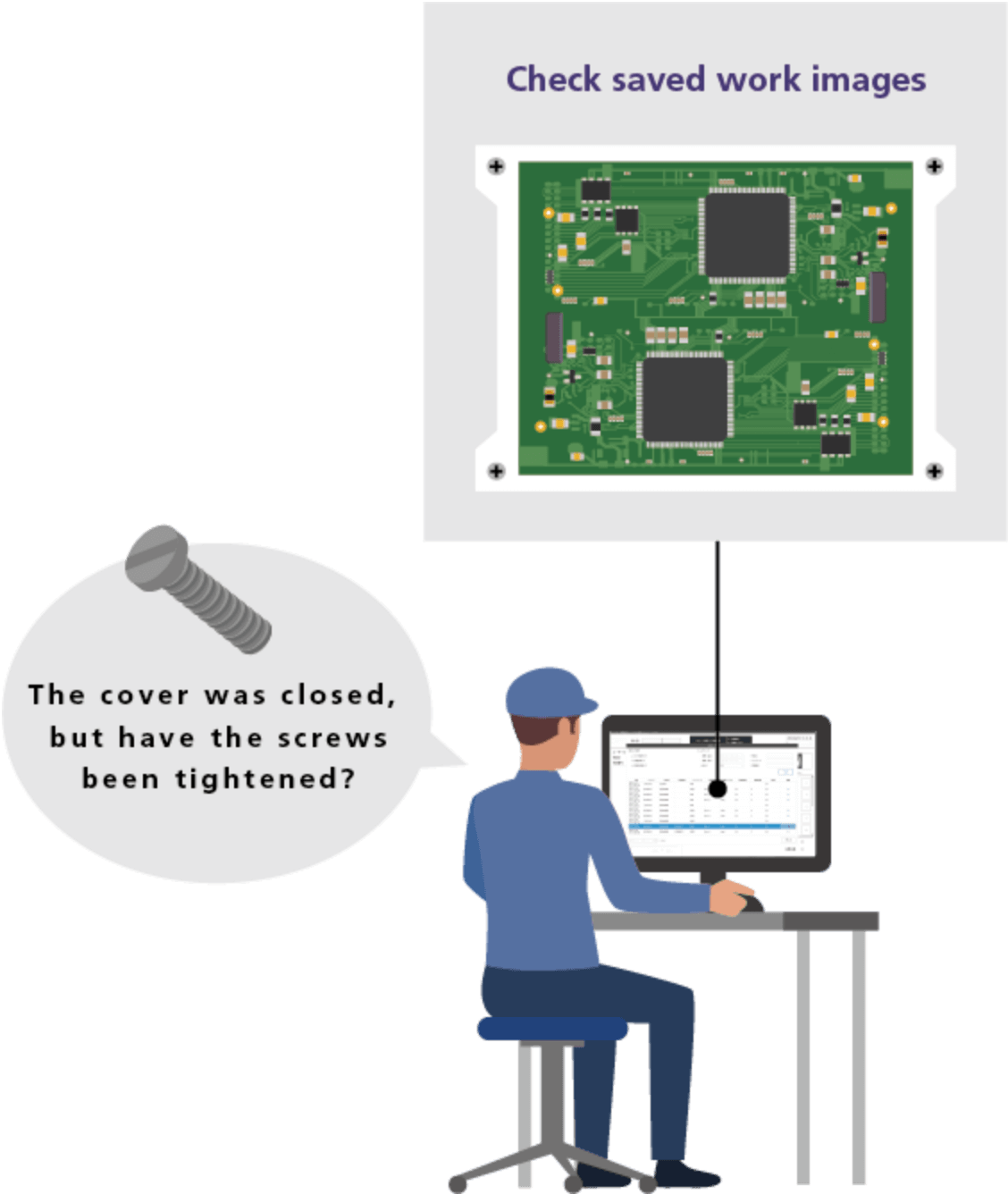

Part serial numbers, work times, etc., and inspection results such as OK/FAIL can be saved as image logs for use in work analysis and traceability.